6. What are the optimum coating parameters for photoresists in order to achieve good film images?

Prior to the coating procedure, resists have to be adjusted to the temperature of the (preferably airconditioned) working area. If the resist is too cold, air moisture may precipitate on the resist. Air bubbles can be avoided if the resist bottle is opened a few hours before the coating step to allow for pressure compensation and left undisturbed (→ Question 7 Air bubbles). Thick resists require several hours for this process, thin resists need less time. Applying the resist with caution and not too fast, using a pipette or a dispenser, also prevents bubbles and inhomogeneities in the resist films.

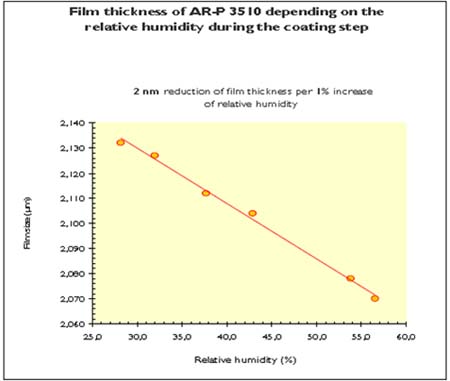

Generally used coating conditions are temperatures of 20~25 °C at a temperature constancy of + 1°C (optimum 21 °C) and a relative humidity of 30~50 % (recommended are 43 %). Higher air humidity reduces the adhesion features significantly. Above 70 % humidity, coating is basically impossible. The air moisture also affects the film thickness (★ diagram).